Sustainable Copper Processing

Eco-Friendly Copper Liberation

Preserving Our Environment Is At The Core Of Everything We Do

Our copper extraction process is environmentally considerate and sustainable. We completely avoid using chemicals and minimise water consumption by utilising a closed-loop recycling system. The ore is processed through a gravity-fed mechanism with straightforward mechanical operations to crush and pulverise it, thereby liberating the copper. Subsequently, shaker tables are used to separate the copper concentrate from the waste material. The waste, primarily silica sand, is repurposed as aggregate for road construction and brick manufacturing.

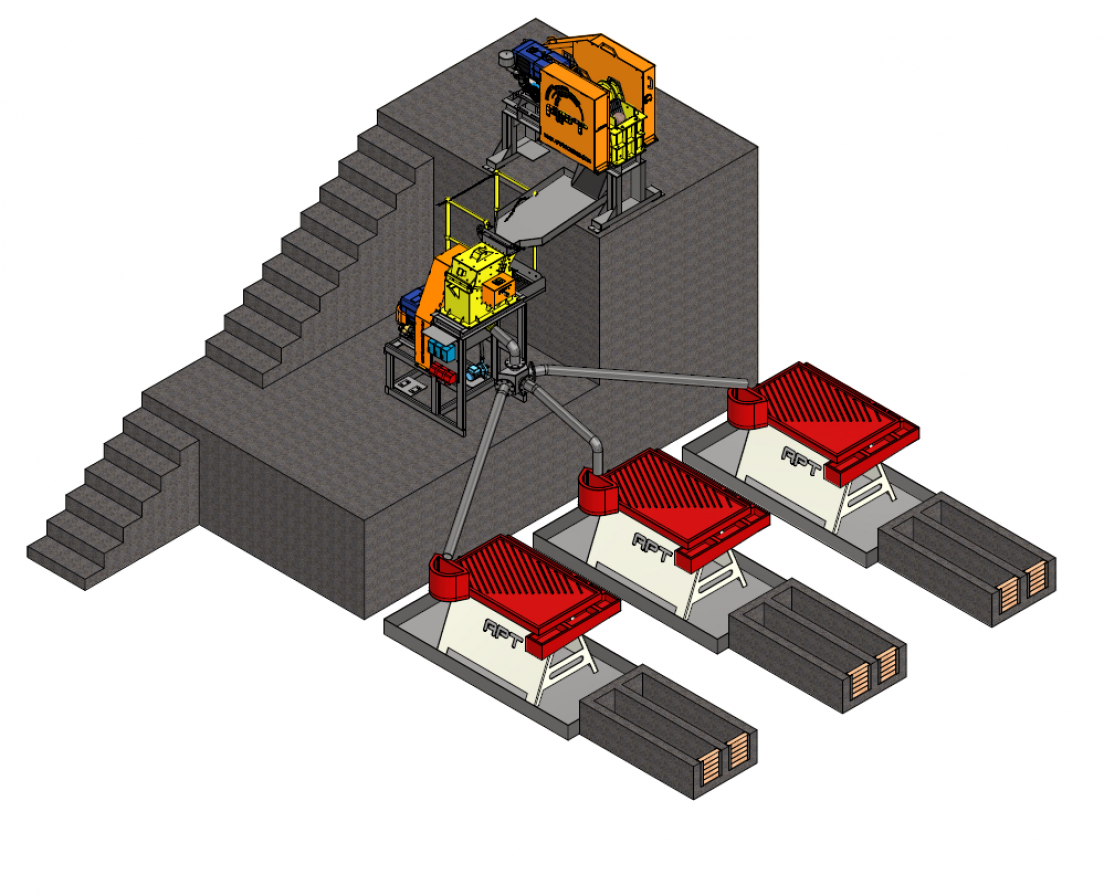

Our Process

The copper liberation process from ore involves three key steps. First, the Run-of-Mine (ROM) is passed through a jaw crusher, where compressive force is applied between a fixed and a moving jaw to reduce the size of the ore particles. In the second step, ore is fed into an impact crusher which breaks down the material by striking it with high-speed blow bars, creating smaller fragments. Finally, in the third step, the coarse ore is processed through a series of shaker tables. These tables utilise a shaking motion combined with water flow to separate the denser copper concentrate from the lighter waste material, resulting in an efficient concentration of copper and disposal of silica sand as aggregate for construction purposes.